Why we recommend Engineered Oak floorboards

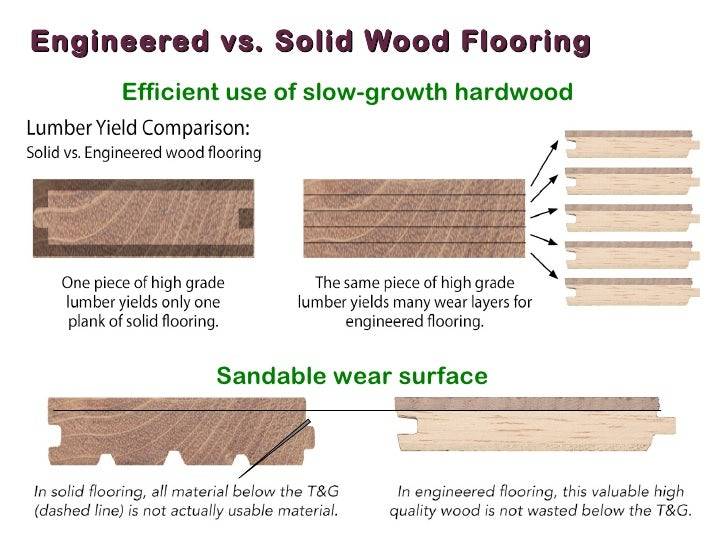

‘Engineered’ refers to the type of construction. You may have thought all floors are the same but the new world of engineered oak floorboards opens up a whole dimension of possibilities for utilizing a precious resource in the most intelligent way possible.

Engineered timber floorboards use multi layered construction to take the internal stress out of the equation – the stress that is responsible for so much of the movement (cupping, crowning, twisting) that frustrates home owners, architects, builders and contractors.

Engineered timber floors also provide an eco-friendly method of utilizing timber resources. Utilizing multiple layers of wood allows superior veneers to be the top ‘wear’ layer whilst the core is made of visually ‘less appealing’ but strong material to provide the perfect combination of structural integrity and beautiful timber to walk on.

Have a look at our wide range of Black Raven Engineered Oak Floorboards.

LED HardWax Oil vs. Other coatings

Revolutionary LED-HardWax Oil contains an unique mix of oils, waxes, resins and additives.

Because of this, the oil cures and hardens in a split second when it comes in contact with LED-light. When finished, the wood surface is instantly resilient and protected against dirt and moist.

LED-HardWax Oil will make the colours of your floor significantly richer and deeper. Suitable for high traffic areas and also for project-based use, because of its high wear-resistance.

The major plus of HardWax Oil is that the floor can be maintained well and that damage to the finishing layer can also be touched up locally. So, you do not need to cover the entire floor to remove minor damage. Due to these possibilities, the floor retains its natural appearance.

Vesting’s oils and (hard) wax oils protect, impregnate, and give many types of wood surfaces a beautiful, distinctive finish. They beautify and provide an excellent moisture and dirt repellent layer.

Using the revolutionary LED-HardWax Oil leads to a superb result. The impact on the environment is minimal and you save an incredible amount in expenditure. With LED technology you use 60% less energy than with traditional UV lamps. Expensive extraction systems are unnecessary because these lamps do not release any harmful ozone. In addition, LED light bulbs have an incredibly long service life, and they generate virtually no heat, which both have a range of associated production advantages. LED-HardWax Oil offers great advantages in terms of production, the environment as well as financially.

- ENERGY saver – LED uses 60% less energy, than traditional UV lamps.

- ENVIRONMENT – no solvents, no ozone emission, and no smell

- REPAIRABLE – Damage to the finishing layer can be easily touched up locally.

- WALK/USE Immediately – Oil dries instantly once activated by LED technology.

- PROTECTION – Suited for high traffic areas because of its high wear resistance.